Stronvar Aerospace Recent Acquisition, Electro Methods Inc, Secures Over $500M in New Orders and Expands Operational Capacity

Stronvar Aerospace is delighted to announce that its Electro Methods Inc. business unit has recently been awarded more than $500 million in new orders from various customers, taking its current order backlog over $1.5bn. To support this growth, the company has fully operationalized its $25 million, 60,000-square-foot expansion in South Windsor, ensuring it is well-equipped to meet increasing customer demand. The expansion takes total footprint on the campus to nearly 250,000 square feet.

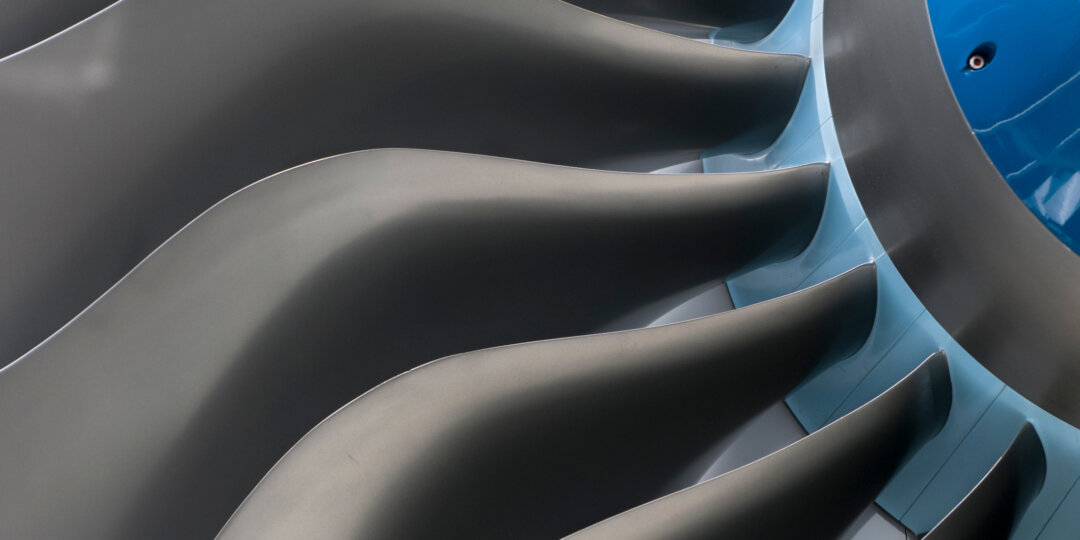

The new 60,000 square foot expansion, which was designed to provide significant capacity for the coming growth, is now fully operational. The expansion is home to 32 CNC vertical turret lathes, 5 axis machining centers, vertical machining centers, laser welding/drilling, six large diameter horizontal-load vacuum furnaces, abrasive flow technology, an FPI line and a dedicated co-located engineering/inspection team. The facility has been designed with further growth in mind, enabling an additional 20,000 square feet of space for incremental technologies and capacity growth. This transformational investment supports Electro Methods Inc to deliver class-leading complex fabricated assemblies while maintaining the highest industry standards.

“These recent contract wins reflect the trust our customers place in us and the strength of our advanced manufacturing capabilities,” said Craig Gallagher, CEO of Stronvar Aerospace. “With our fully operationalized facility, we are focused on growing the employee skill base and developing the excellent culture that we have here in South Windsor. In tandem we are looking to develop our lean manufacturing processes to ensure that we are equipped to meet the needs of our customers in an efficient manner as the business continues to expand.”

Bill Soucy, President of Electro Methods, added, “We have been successfully growing over recent years and are excited about the next phase of growth at Electro Methods. Our goal is to double output before the end of the decade, ensuring that we maintain our strong engineering quality signature so that we stay ahead of our customers’ increasing needs. By controlling manual, robotic and electron- beam welding, complex machining, complex fabrication heat treatment, EDM, and brazing all in- house we can deliver best-in-class performance to our customers. With the backing of Stronvar we are positioned for sustained expansion, including plans for additional engineering and office space by year-end.”

These new contract wins and facility expansion at Electro Methods represent early milestones for Stronvar Aerospace, aligning with the company’s strategy to enhance operational efficiency, reduce lead times, and support the aerospace industry’s evolving technological needs. The South Windsor site sits in a region of rich manufacturing and engineering talent; these investments will also create new job opportunities, further contributing to the local economy and the skilled manufacturing workforce.